Maxzimus Steel Building (MSB) is known among consultants, engineers, developers and project

owners as THE

RELIABLE SOURCE IN Pre-Engineered Steel Buildings (PEB).

Since its inception, MSB has grown to become one of the major suppliers of Pre-Engineered

Buildings

(PEB).Frames of pre-engineered buildings are made from an extensive inventory of standard plates

stocked by

the PEB manufacturer. PEB frames are normally tapered and often have flanges and webs of

variable

thicknesses along the individual members

Pre-engineered buildings are on the average 30% lighter through the efficient use of steel.

Primary framing

members are tapered (varying depth) built- up plate sections, with larger depths in the areas of

highest

stress.PEB engineers design and detail preengineered buildings almost every day throughout the

year

resulting in faster and more efficient designs.

Quick and efficient; since PEB’s are mainly formed of standard sections and connections, design

time is

significantly reduced. Basic designs are used over and over.

Specialized computer analysis and design programs optimize material required. Drafting is also

computerized

using standard details that minimize project custom details.

Design, shop detail sketches and erection drawings are supplied free of charge by the

manufacturer. Approval

drawings are usually prepared within 2 weeks.

Simple design, easy to construct and light weight. Since the connections of the components are

standard,

the learning curve of erection for each subsequent project is faster. Periodic free-of-charge

erection

support at the site is usually provided by PEB manufacturers.

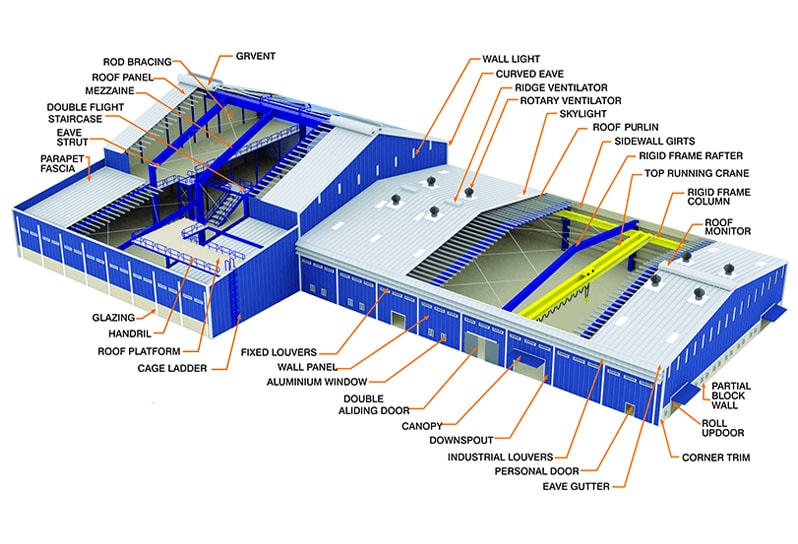

The PEB Steel Structure of a Pre-Engineered Steel Building generally accounts for over 80% of the weight of the Pre-Engineered Steel Building. This 80% is an average and may change plus or minus 10% depending on the presence of mezzanines, crane runway beams, type of Panels used and the amount of building accessories that are included in a building. The unit of measure for PEB Steel Structures is metric ton (MT). As a general average, one square meter (1 m²) of PEB Steel Structure weighs 25 kg. Thus one MT of PEB Steel Structure = 40 (1000/25) m² of building foot print. The PEB Steel Structure is made up of frames, secondary members and steel standard buyouts.

Frames in the PEB industry often refer to primary built-up & hot rolled members. Constant depth or tapered depth built-up members generally account for over 90% of the weight of frames while hot rolled members generally account for the remaining 10%.

Secondary Members in the PEB industry refer mostly to longitudinal roof and wall members that are roll formed from galvanized coils or press broken from narrow galvanized sheets. The raw material of these members is stocked in five thickness: 1.5, 1.75, 2.2, 2.25 and 2.5mm.

The following building components are considered secondary members:

- Z" sections acting as longitudinal roof purlins and longitudinal wall girts that connect to columns & rafters and support exterior roof and wall panels.

- Eave struts located at the building eaves (corner of roof and wall sheeting along sidewalls also providing bracing for frames and supporting roof and wall panels.

- "C" sections used primarily in framed openings and as a transition member between partial block walls and wall panels.

- Mezzanine Deck (0.7mm thick) used to support concrete slabs in second level flooring.

- Base angles, gable angles, and mezzanine edge angles.

- Valley gutters (0.9mm thick) in Multi Gable Buildings.

- Steel Standard Buyouts (SBO): These are items that are required in almost every PEB Steel Structure. They are manufactured by others and stocked by the PEB manufacturer. They include Anchor Bolts, Connection Bolts, Sag Rods and Cable Bracing Components.

MAXZIMUS STEEL BUILDING P LTD

THE RELIABLE SOURCE

MAXZIMUS STEEL BUILDING P LTD

THE RELIABLE SOURCE

MAXZIMUS STEEL BUILDING P LTD

THE RELIABLE SOURCE

MAXZIMUS STEEL BUILDING P LTD

THE RELIABLE SOURCE